Light Source in LED Lighting – Definition and Classification in Safety Standards

Most people have at some point replaced a lamp in a luminaire. For a long time, the lamp was almost synonymous with a light source – a simple and clear component that everyone knew how to replace.

LED technology has changed this. A light source is no longer just a lamp but can also be, for example, a semi-integrated, built-in, non-user replaceable LED module.

Light source replaceability is usually associated with ecodesign and sustainability.

However, in safety standards, light source replacement is not examined from a sustainability perspective, but purely from the viewpoint of electrical safety.

What is a light source according to standards?

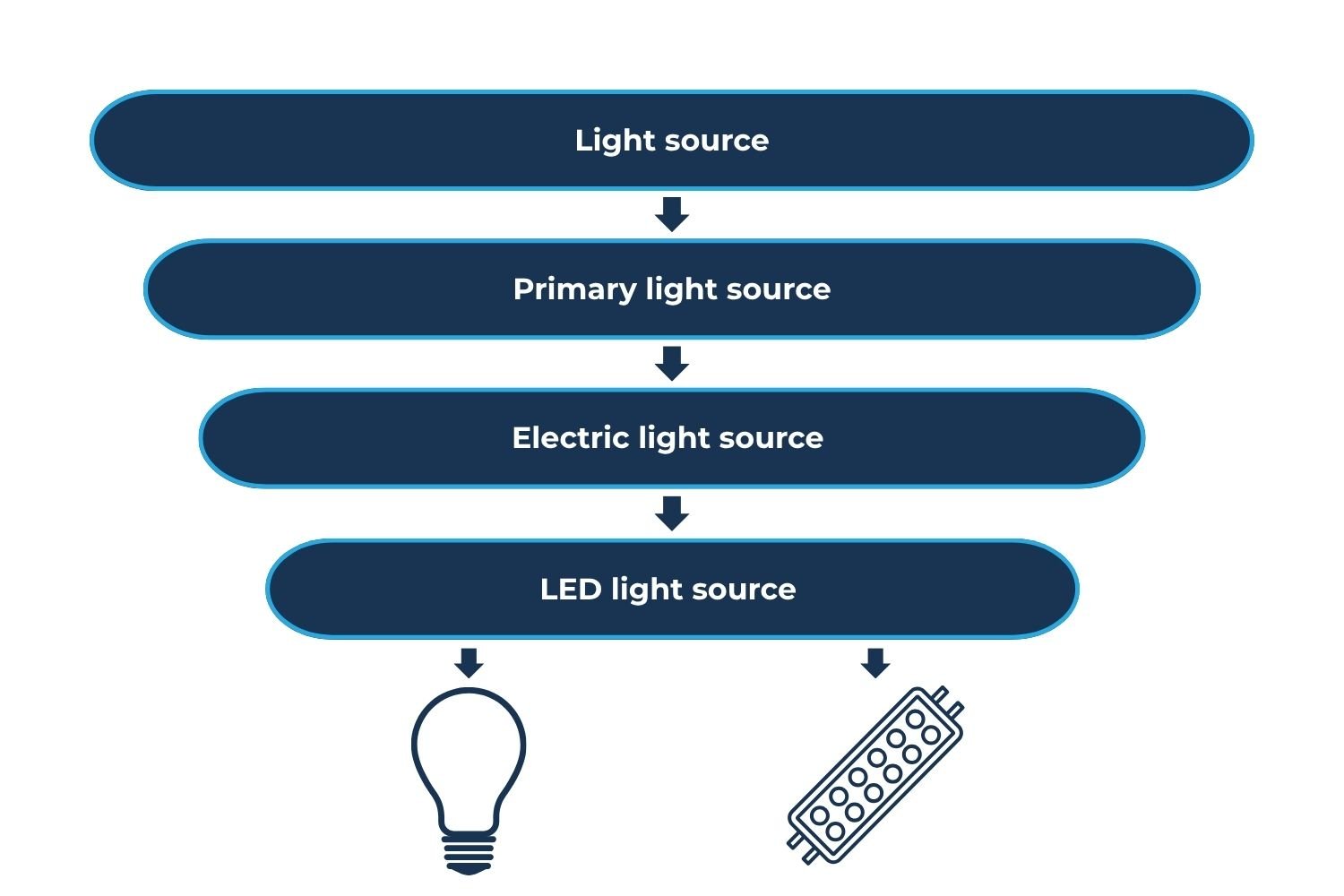

The International Electrotechnical Commission (IEC) defines the term "light source" broadly. According to the IEC, a light source is " surface or object emitting light".

There are, however, more specific sub-definitions such as:

Primary light source: surface or object emitting light by a transformation of energy

Electric light source: primary light source with the means for connecting to the power supply and usually designed to be incorporated into a luminaire

LED light source: electric light source based on LED technology

There are different types of LED light sources, the most commonly known being:

LED lamp: electric lamp based on LED technology

LED module: LED light source having either at least one PCB cap or no cap, and incorporating at least one LED package

How are light sources classified?

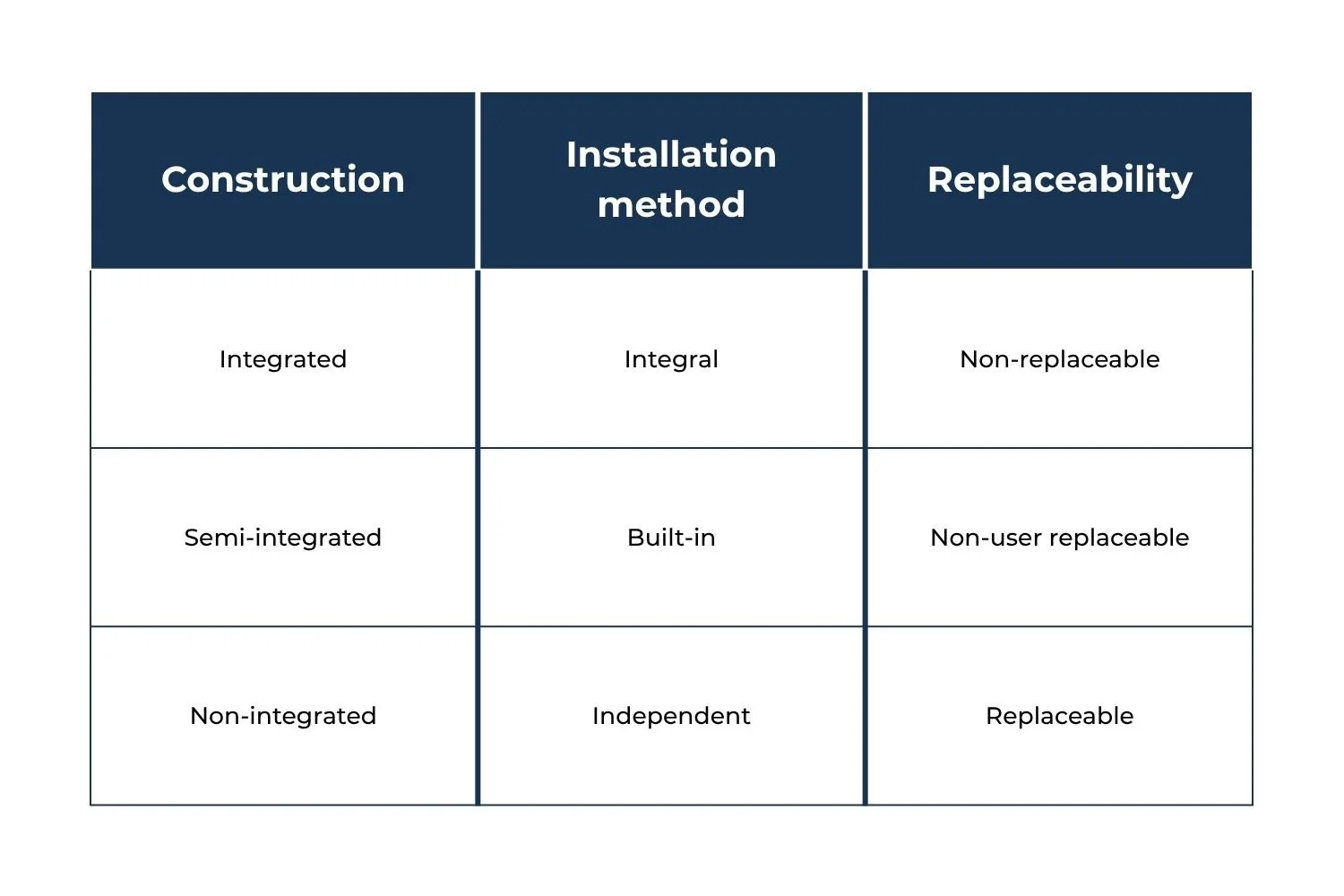

In standards, light sources are classified according to their construction, installation method, and replaceability. The following focuses on the classification of LED lamps and modules.

Classification by construction

LED lamps and modules are classified into three categories based on construction or level of integration of control gear:

Integrated LED lamps and modules (LEDi) include the control gear and any additional elements necessary for stable operation of the light source. They are designed to connect directly to supply voltage. For example, a standard E27 LED lamp is an integrated LED lamp.

Semi-integrated LED lamps and modules (LEDsi) carry the control unit of the control gear, and is operated by the separated power supply of the control gear. The control unit is a device or circuit that controls the electric energy to the LED light source (e.g., for colour mixing, responding to depreciating luminous flux, and other features).

Non-integrated LED lamps and modules (LEDni) need a separate control circuitry or control gear to operate. This includes for example common constant current LED modules and 12V LED lamps.

Classification by installation method

Light sources and other components are also classified based on how they are installed or used. This classification applies to LED modules, but not lamps.

Built-in LED module is designed to form a replaceable part built into a luminaire and not intended to be mounted outside a luminaire.

Integral LED module is designed to form a non-replaceable part of a luminaire and is not replaceable.

Independent LED module is designed for mounting or placing separately from a luminaire and includes all required protection and markings.

Classification by replaceability

Light sources are also classified by their replaceability:

Replaceable light source: light source designed to be replaced by an ordinary person or a skilled person

Non-user replaceable light source: replaceable light source intended by the manufacturer to be replaced only by a service agent, or a similarly skilled person

Non-replaceable light source: light source designed to be a non-replaceable part of the luminaire

Replaceability is not only a property of the light source itself but also depends on the luminaire's construction.

For example, a replaceable light source installed in a luminaire can be classified as replaceable, non-user replaceable, or non-replaceable, depending on the luminaire design.

Replaceability is partly linked to installability – for example, an integral LED module is always a non-replaceable light source.

How does classification affect safety?

The classifications by construction, installation method, and replaceability are not safety requirements themselves, but they guide how safety is implemented in practice.

These classifications form the basis for several safety requirements that define the protection and testing requirements for different types of light sources.

The main standards applying these classifications are:

IEC 60598 – safety standard series for luminaires

IEC 62031 – safety standard for LED modules

IEC 63554 (in development) – new safety standard for LED lamps

Safety from a construction perspective

The construction class affects product safety primarily at the light source level. The classification provides guidance on voltage and insulation levels, which determine the necessary protection mechanisms.

Integrated light sources are designed to be connected directly to mains voltage, so their protection must be dimensioned accordingly.

In semi- and non-integrated sources, the requirements depend on the controlgear’s voltage and insulation characteristics.

Safety from an installation method perspective

From the perspective of installation method, safety is partly related to replaceability and partly to the "two lines of defense" principle — where the product remains safe even if one protection fails.

In this principle, the luminaire, control gear, and light source together form a complete protection system. For example, the control gear may provide basic insulation between the mains voltage and the output circuit supplying the LED module (first line of defense), while the built-in LED module itself has basic insulation between its live internal parts and accessible outer surfaces (second line of defense).

How this overall protection is achieved in the case of integral and built-in modules is always case-specific.

In an independent LED module, both lines of defense must be provided within the module itself.

Safety related to light source replacement

In luminaire safety standards, the replaceability of a light source is not considered from a sustainability viewpoint but strictly from the risk of electric shock.

The standard is based on a worst-case scenario: replacement is attempted while the luminaire is energized.

Even if replaceability terms define whether a light source can be replaced and by whom, from a safety perspective, replacement must be considered as follows:

Hazardous live parts shall not be accessible during the replacement of replaceable light sources.

If a non-user replaceable light source contains hazardous live parts, they must be protected with a cover requiring a tool to remove and marked with a electric shock risk symbol.

With non-replaceable light source, it shall not be possible to replace light source or to give access to hazardous live parts without breaking the luminaire or its parts.

Why does classification matter?

The classification of light sources is not just a technical detail – it directly affects how a product is designed, documented, and tested.

For example, although LED modules have their own safety standard (IEC 62031), independent modules must also meet the requirements of the luminaire standard. Testing requirements also differ – replaceable and non-user replaceable LED modules have different heat management requirements.

Classification also affects markings and user instructions. For instance, luminaire standards specify exactly what needs to be included in the documentation for non-user replaceable and non-replaceable light sources.

Correct classification benefits not only safety but also usability. When LED module manufacturers clearly define the classification, it helps luminaire manufacturers implement compliant protection measures.

Likewise, when the luminaire manufacturer clearly defines light source replaceability, misunderstandings and potential safety issues during replacement can be avoided.

Summary

The concept of a light source has evolved with technology and is no longer synonymous with a lamp. LED technology has introduced various types of light sources, each with different classifications. In safety standards, light source classification is not based on energy efficiency or recyclability, but on how product safety is ensured in different installation and servicing situations.

Classification by construction, installation method, and replaceability directly impacts how a product is designed, tested, marked, and documented. Replaceability, in particular, plays a key role in both user safety and compliance.

Proper classification also facilitates cooperation between light source, controlgear, and luminaire manufacturers – and helps prevent safety hazards and misunderstandings in real-world use.